Toyota Faces Financial Strain Amid Global Chip Shortage

The automotive giant Toyota has been grappling with significant disruptions due to the global chip shortage. This shortage has not only impacted production lines but also severely influenced the company’s financial health. Over recent months, the crisis has escalated, causing ripples across the industry.

The Chip Shortage Crisis

Semiconductors are essential components in modern vehicles, controlling everything from engine management to infotainment systems. The unprecedented demand for chips in various sectors, coupled with supply chain disruptions, has led to a severe shortage. Toyota, like many other automakers, has felt the brunt of this supply chain tumult.

While the demand for vehicles is robust, the inability to procure necessary chips has forced Toyota to scale back production. Factories have had to shut down temporarily or reduce their output, leading to fewer cars being available for sale. This bottleneck has a direct impact on revenues and profit margins.

The situation has become so dire that some production facilities have had to operate at half their capacity. This reduction in output has affected not only the availability of new models but also the launch timelines of upcoming vehicles. Consumers eagerly waiting for the latest Toyota models may have to exercise patience as the company navigates through this challenging period.

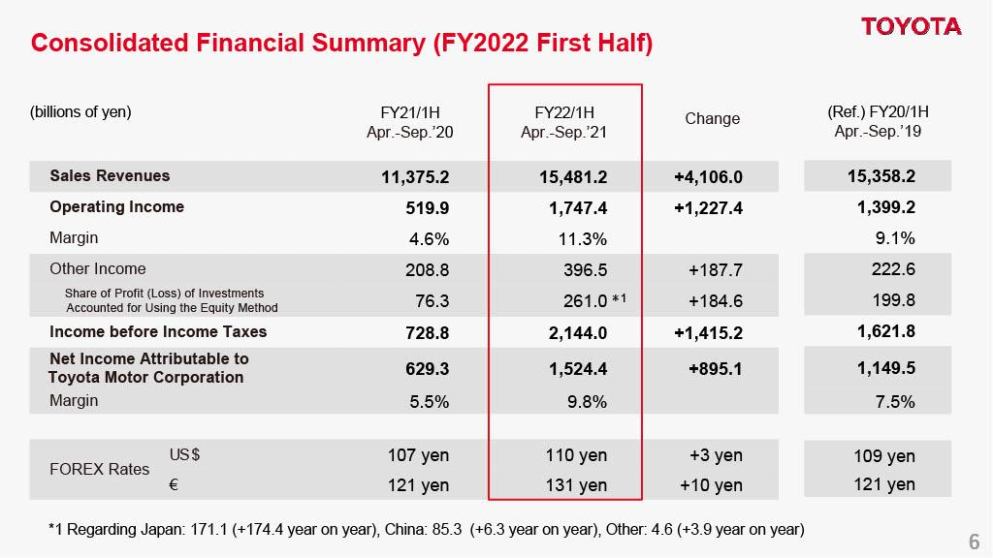

Financial Implications for Toyota

Toyota’s quarterly profits have taken a hit due to the ongoing chip shortage. The company, which has a reputation for efficient supply chain management, has found itself in an unprecedented situation. The shortage has led to increased costs as Toyota scrambles to secure the chips necessary for their vehicles.

These financial strains are not limited to just one quarter. Analysts predict that the impact will be felt for several quarters, if not years. The ripple effect of the chip shortage is evident in the company’s stock prices, which have seen fluctuations in response to production updates and financial forecasts.

Moreover, the increased cost of raw materials and logistics has further strained Toyota’s finances. The company has had to make tough decisions, such as delaying certain investments and focusing on core models that promise higher returns. This strategic pivot is crucial for Toyota to maintain stability during these turbulent times.

Global Supply Chain Disruptions

The pandemic has exacerbated the challenges faced by global supply chains. Factories in various parts of the world have had to deal with lockdowns, labor shortages, and logistical hurdles. These factors contribute to the overall delay in chip production and distribution.

For Toyota, which sources components from various global suppliers, the complexity of the situation increases. The company has had to navigate through a web of challenges to maintain its production levels. Yet, despite their efforts, the shortage continues to loom large.

Addressing these supply chain issues requires a coordinated effort from various stakeholders, including governments, suppliers, and manufacturers. The industry is keenly watching how Toyota and other automakers adapt to these challenges in the coming months.

In response to these disruptions, Toyota has ramped up its communication and collaboration with suppliers. This proactive approach aims to identify potential bottlenecks early and devise contingency plans. However, the unpredictability of the situation means that even the best-laid plans can face unforeseen hurdles.

Adaptation and Future Strategies

Toyota has been exploring various strategies to mitigate the impact of the chip shortage. This includes diversifying their supply chain, investing in chip production, and collaborating with tech companies. These efforts aim to create a more resilient supply chain capable of withstanding future disruptions.

Moreover, the company is looking into alternative technologies that could reduce dependency on traditional semiconductor chips. Innovations in this area could potentially revolutionize the automotive industry. Toyota’s commitment to research and development is a testament to their forward-thinking approach.

In addition to technological innovations, Toyota is also focusing on building stronger relationships with chip manufacturers. By forging long-term partnerships and investing in joint ventures, Toyota aims to secure a steady supply of critical components. These strategic alliances could prove pivotal in weathering the current crisis and safeguarding against future shortages.

Consumer Impact

The chip shortage has not only affected manufacturers but also consumers. Prospective car buyers are facing longer wait times and limited options. The scarcity of new vehicles has also driven up prices, making it a challenging market for buyers.

Dealerships are struggling to keep up with demand, and many have reported dwindling inventories. This situation has led to a surge in the used car market, where prices have also seen a significant increase. Consumers are having to make tough decisions amidst these market conditions.

For many buyers, the decision to purchase a vehicle has become a balancing act between urgency and availability. Some are opting for immediate purchases of available models, while others are willing to wait for their preferred configurations. This dynamic has reshaped consumer behavior in the automotive market.

Industry-Wide Repercussions

The impact of the chip shortage extends beyond Toyota. The entire automotive industry is feeling the strain. Companies are reevaluating their supply chains and seeking ways to become more self-reliant. Collaborative efforts and industry-wide initiatives are being discussed to address the shortages.

While Toyota has been proactive in its approach, other automakers are also stepping up their game. The competition to secure chip supplies has intensified, with companies striking deals and forming alliances to ensure their production lines keep running.

- Increased collaboration between automakers and tech companies

- Investment in local chip manufacturing facilities

- Exploration of alternative materials and technologies

The automotive industry is entering a phase of transformation, driven by the need to adapt to new realities. The chip shortage has served as a wake-up call, highlighting vulnerabilities and prompting a reevaluation of traditional practices.

Industry leaders are now more focused than ever on creating a robust and flexible supply chain. This transformation is expected to bring about lasting changes, making the industry more resilient to future disruptions. The lessons learned during this crisis will likely shape the strategies and priorities of automakers for years to come.

Looking Ahead

The road ahead is fraught with challenges, but also opportunities. Toyota’s response to the chip shortage will shape its future trajectory. The company’s ability to innovate and adapt will be crucial in navigating this crisis.

Despite the current difficulties, Toyota remains committed to its long-term goals. Sustainability, technological advancement, and customer satisfaction continue to be at the forefront of their strategy. The lessons learned from this crisis will undoubtedly influence the company’s approach in the years to come.

In conclusion, the global chip shortage has created a complex scenario for Toyota and the entire automotive industry. The financial implications are significant, but so are the opportunities for growth and innovation. As Toyota navigates these challenges, the world watches closely, eager to see how one of the automotive giants will emerge from this crisis.

Ultimately, the resilience and adaptability of Toyota will be tested like never before. The company’s legacy of innovation and excellence provides a strong foundation, but the path forward will require bold decisions and strategic foresight. As the industry evolves, Toyota’s journey through this crisis will serve as a case study in overcoming adversity and driving progress in the face of unprecedented challenges.